Dimister

ENHANCED PERFORMANCE AND PROTECTION FOR YOUR COMPRESSED AIR SYSTEM

The auditors choice to reduce energy costs and remove oil and water aerosols from compressed air system.

The auditors choice to reduce energy costs and remove oil and water aerosols from compressed air system.

- Protect products and processes from contamination.

- Increase the life of pneumatic equipment.

- Help eliminate paint appearance and adhesion problems.

- Keep pneumatic instruments operating

- Low pressure drop: 0.5 to 1 psi (0.04 to 0.07 kgf/cm²) – Typical coalescing filters operate at 3 to 6 psi (0.21 to 0.42 kgf/cm²) requiring the air compressor to operate at higher operating pressures, increasing power requirements by 2.5% or more.

- Long element life: 8 to 15 years with a large in-depth bed, element life is much longer than conventional oil removal filters.

- Virtually maintenance free

- Captures and retains large sluges of oil and water should drain trap fail.

- Protects downstream equipment from contamination should oil separator on rotary screw compressor fail.

- 5 year equipment warranty.

- 5 year element life guarantee.

- Differential pressure gauge mounted and piped.

- Heavy duty ASME stamped pressure vessel.

- Floor stand.

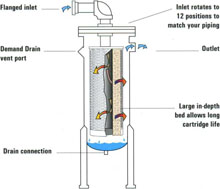

- Dedicated vent port for demand type drains.

- Twelve (12) inlet positions to better adapt to your piping arrangement.

- Inlet piping clears vessel diameter to prevent element removal complications

- Flanged inlet connection ensures easy access to element.

- Dedicated vent connection port for clean, easy demand drain trap installations.

- 100% of particles 3 microns and larger.

- 99.98% of particles 0.1 micron and larger.

- 0.5 ppm w/w maximum liquid content after filtration.

- 1000 ppm maximum inlet liquid loading.

- Automatic condensate drains:

- No-Loss drains (NLD-24-T shown)

- Timer drains

- Differential pressure gauge with reed switch.

YANGTECH ENGINEERING CO., LTD.

Taiwan Contact Information :

TEL : +886-2-8751-3737

FAX : +886-2-8751-3232

E-Mail:[email protected]

Address :

China Contact Information :

TEL : +86-21-6127-6200

FAX : +86-21-6127-6202

E-Mail:[email protected]

Address :