KHE and KHL

For decades, compressed air users have relied on Kemp to deliver technology that reduces the cost of operation and improves the reliability of air driven processes. The KHE Series, KHL Series are engineered to deliver ISO 8573.1 Air Quality with dew point performance guaranteed from 40 to 5,400 scfm.

THE KEMP GUARANTEE

Kemp guarantees that KHP Series dryers will produce the design dew point while operating continuously at maximum rated flow (100% duty cycle ) at CAGI ADF 200 inlet standards of 100℉ inlet temperature and 100% relative humidity at 100 psig.

CONSISTENT OUTLET PRESSURE DEW POINTS Industry-leading Desiccant Beds

THE KEMP GUARANTEE

Kemp guarantees that KHP Series dryers will produce the design dew point while operating continuously at maximum rated flow (100% duty cycle ) at CAGI ADF 200 inlet standards of 100℉ inlet temperature and 100% relative humidity at 100 psig.

CONSISTENT OUTLET PRESSURE DEW POINTS Industry-leading Desiccant Beds

- Industrial grade activated alumina desiccant beads offter enhanced surface area and high crush strength which prolongs bed life.

- Large desiccant beds ensure 4.8 seconds contact time… allows wet, saturated air at the dryer inlet to be dried to the required dew point.

- Industrial grade desiccant ensures top performance over expected 3 to 5 years of desiccant bed life.

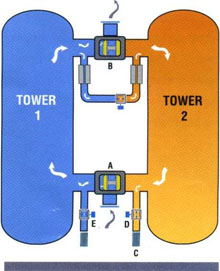

- Large flow diffusers ensure even flow distribution through the bed and eliminate channeling.

- Towers are sized so that air velocity through the bed won't fluidize the desiccant which prevents bed movement and desiccant dusting.

- Up-flow drying allows water and heavy contaminants to drop out of the air stream as they enter a tower which protects the bed from contamination. This makes it simple to discharge the contaminants when the tower depressurizes.

- Cleanable stainless steel flow diffusers / support screens and separate fill and drain ports for ease of desiccant replacement.

- Pressure vessels are CRN and ASME Certified.

- Heavy-duty mufflers for quiet operation-dryers are shipped with an extra set of mufflers.

- NEMA4 electrcal construction is standard.

- Pressure relief valves are standard.

YANGTECH ENGINEERING CO., LTD.

Taiwan Contact Information :

TEL : +886-2-8751-3737

FAX : +886-2-8751-3232

E-Mail:[email protected]

Address :

China Contact Information :

TEL : +86-21-6127-6200

FAX : +86-21-6127-6202

E-Mail:[email protected]

Address :