KZP

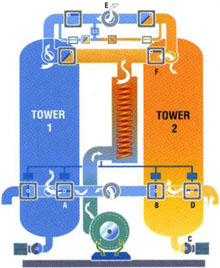

For decades, compressed air users have relied on Kemp to deliver technology that reduces the cost of operation and improves the reliability of air driven processes. KZP Series dryers improve air system efficiency by the use of a dedicated axial blower, instead of a percentage of dehydrated purge air, to regenerate the offline desiccant tower. ISO 8573.1 Class 2(-40℉/-40℃) dew point performance is guaranteed.

REDUCE ENERGY CONSUMPTION

As the air compressor is the most costly system component to purchase, and it uses more electrical energy than the rest of system combined, it is wise to ensure that the smallest air compressor is installed. KZP Series dryers are 100% efficient at delivering full supply-side compressor capacity. Therefore, users benefit from the ability to purchase a less expensive air compressor and a 20% reduction in compressor operating costs.

THE KEMP GUARANTEE

Kemp desiccant dryers are guaranteed to produce the design dew point while operating continuously at maximum rated flow (100% duty cycle) at CAGI ADF 200 inlet standards of 100℉ inlet temperature and 100% relative humidity at 100 psig.

ELIMINATE COSTLY COMPRESSED AIR LOSS

Global competition, spiraling energy costs and the challenge to “do more, with less” require manufacturers to closely examine operating costs. Compressed air generation tends to be the most costly utility within a facility. Eliminate air loss to align supply-side equipment with demand-side requirements to optimize your air system.

REDUCE ENERGY CONSUMPTION

As the air compressor is the most costly system component to purchase, and it uses more electrical energy than the rest of system combined, it is wise to ensure that the smallest air compressor is installed. KZP Series dryers are 100% efficient at delivering full supply-side compressor capacity. Therefore, users benefit from the ability to purchase a less expensive air compressor and a 20% reduction in compressor operating costs.

THE KEMP GUARANTEE

Kemp desiccant dryers are guaranteed to produce the design dew point while operating continuously at maximum rated flow (100% duty cycle) at CAGI ADF 200 inlet standards of 100℉ inlet temperature and 100% relative humidity at 100 psig.

ELIMINATE COSTLY COMPRESSED AIR LOSS

Global competition, spiraling energy costs and the challenge to “do more, with less” require manufacturers to closely examine operating costs. Compressed air generation tends to be the most costly utility within a facility. Eliminate air loss to align supply-side equipment with demand-side requirements to optimize your air system.

YANGTECH ENGINEERING CO., LTD.

Taiwan Contact Information :

TEL : +886-2-8751-3737

FAX : +886-2-8751-3232

E-Mail:[email protected]

Address :

China Contact Information :

TEL : +86-21-6127-6200

FAX : +86-21-6127-6202

E-Mail:[email protected]

Address :